Converting Machine

Toilet Roll Converting Line

Toilet roll converting line consists of toilet roll rewinder, automatic log supply, log cutter, and roll wrapping machine.

Not only performance of each machine, also efficient layout of those machines significantly affect production efficiency.

We can also offer embossing unit, log accumulator, automatic log sorting unit as optional equipment. Kawanoe propose optimal layouts for the efficient use of space, including optional equipment, that lead directly to higher production efficiency.

Production process

-

Toilet Roll Rewinder

90K-H, TR-7 -

Log Accumulator

LA-90 -

Log Cutter

LC-21 series -

Single toilet roll wrapping machine

TW-90S

Toilet Roll Rewinder TR-7 Fully Automatic

Shaft-less mechanism,

Fully automatic non-stop operation

Features

- - Mechatronics integrated system

- - Efficient and space saving

- - Stable and high quality production

- - The ultimate in safety

- - Integrated control on touch panel

Log Cutter LC-21 series

Max. 200 cut/min.

Large capacity high speed production

Features

- - Large capacity and high speed production

- - Flexible setting of cutting length of log

- - One-touch adjustment of the clamps

- - Movable log clamp

- - Automatic blade grinding system

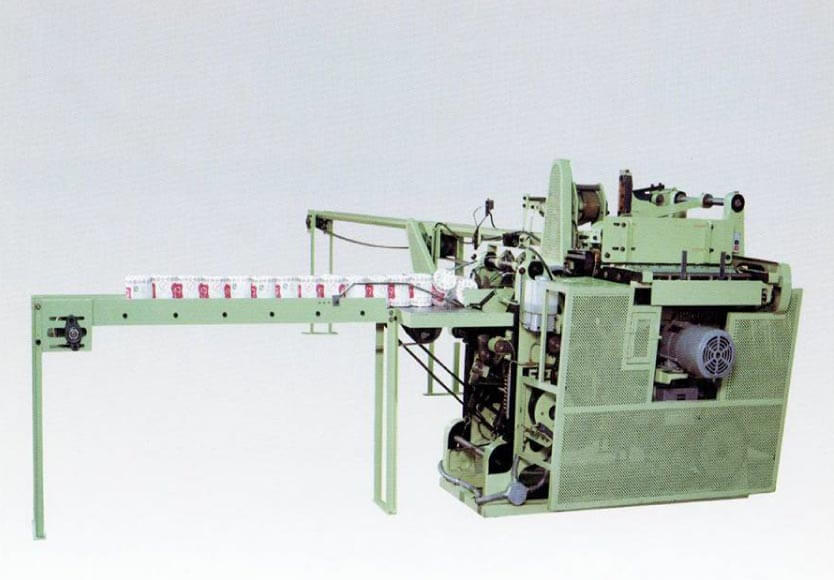

Boxed Tissue/Kitchen Towel Converting Line

Boxed tissue/Kitchen towel converting line consists of tissue interfolder, tissue cutter, and cartoning machine. Many types of layout are possible to match the available installation area and scale of production. Even thin tissue paper can be folded, which reduces cost and allows the use of automated product take-out equipment, which saves on labor in the converting line.

Production process

-

Interfolder IF-21

-

Cutting equipment

-

Accumulator

-

Final product by cartoning

machine or wrapping machineBox tissue

Paper towel

Interfolder IF-21

Labor saving and highly efficient

Fully automatic interfolding.

Precision center folding and sheet counting

Features

- - New design and high speed processing

- - Sharp cut ends and long-life blade

- - Accurate, beautiful folding

- - Automatic speed adjusting unreel

- - Applicable to wide range of paper

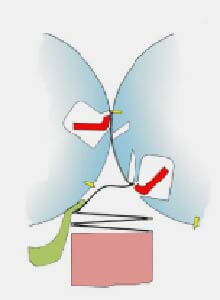

Fully automatic high speed Interfolder IF-21

□ Folding configuration : interfolding

□ Folding roll

Folding mechanism equipped with rotary holding ensures accurate center folding allowing accurate and non-stop interfolding

Ply Machine

Improve quality of 2-ply/3-ply

Our ply machine conduct plying,

slitting and rewinding

◆ Suitable for 2-ply/3ply for tissue, toilet, napkin, and non-woven fabric

◆ Facilitating operation – equipped with various desired functions

Features

- - High speed operation at 1,200m/min.

- - Applicable to wide range of paper grades – from crepe paper to non-woven fabric

- - Automatic tension control function

- - Quick parent roll change

- - Simple and trouble-free stable operation

- - Space saving

Toilet Roll Fully Automatic Kraft Paper Wrapping Machine

Toilet papers used to be transferred to retailors from tissue mills after they packed in cardboard of 8 sets of 12 rolls.

However, in recent years, craft papers that can be replaced by cardboard are spotlighted in terms of efficiency and cost.

Our wrapping machine wraps toilet rolls tightly using craft paper.

Our random roll wrapping machine meets our customer’s requirements.

Toilet Roll Fully Automatic Kraft Wrapping Machine

Features

- - Complete wrapping with one operational supervisor

- - Wrapping capacity 8 cases / hour

- - Easy to operate using touch panel

- - Fully automatic wrapping for various size of roll

- - Consistent high quality wrapping

- - Can be exchanged with existing cardboard wrapping machine due to its compact design

- - Reduce the time to display the products and easy to dispose

Actual picture of wrapping