OUR STAFFS

INTERVIEW

“Ideal that I want to pursue” This is what I found in Kawanoe Zoki.

Atsushi Mitsumata

Designing section, joined in 2015

Reason why I chose to work for Kawanoe Zoki

During my job hunting process, I focused on the business description and social contribution of the companies. I have been curious about machines and had passion to manufacture by myself since my childhood. And this leaded me to work for Kawanoe.

Another point is that Kawanoe Zoki designs and manufactures tissue making and converting machine that produces essential papers in our daily life.

The fact that most of hygiene papers in domestic are produced by our machines attracted me as well.

Present job

I belong to tissue making machine designing section. And I am mainly in charge of rebuild projects. Since I am still new to this, I get a lot of advice from my seniors during my process of work.

Rebuild projects are not the same as new machine projects and require flexibility to comply with irregular matters. It sometimes confuses me how I can proceed, at the same time, is very good experience for me.

The project that left the biggest impression on me

In the project I was in charge of, we could not meet the customer’s delivery time and ended up bothering not only our customer but our other colleagues.

The cause of the delay was due to my poor experience.

Since then, I learned to keep in mind to work on every project from the different points of view.

Motivation

In my first project, the problem happened. At test-run, the sheet didn’t flow smoothly on the conveyor. We tried hard to adjust it and finally it went well with technical approach. I felt very good, challenging and gained my confidence when the problem was solved.

Kawanoe is a company where I can contribute to the society with my knowledge and experience

Kazuya Yamamoto

Manufacturing technology section, joined in 2013

Reason why I chose to work for Kawanoe Zoki

I wanted to pursue my career in manufacturing and work for my hometown here in Ehime.

I got to know this company from my university professor and heard that there are my seniors from my university working for the company. Then, I decided to participate in the company information session.

We were guided to mill tour taking look at machining. I determined to work for this company for the reasons that I can apply my knowledge in this company.

Present job

I belong to manufacturing technology section and am in charge of programming of machining, maintenance of machining equipment, procurement for tools and parts and product inspection.

My main task is programming of machining.

I make programming considering how they can be the most efficient and precise machining in the process. There are a lot of things to learn and thanks to my senior advice I can move forward day by day.

The project that left the biggest impression on me

The problem happened during plating on the embossing roll surface at our supplier. In the previous meeting with the supplier, they informed us it is 100% success rate and we trusted it. We regretted that we didn’t confirm things we needed to. I learned and recognized that we need to confirm in detail and do what we ought to do.

Motivation

I feel motivated when I get my task done as expected by my seniors and bosses.

Kawanoe Zoki has complete know-how of manufacturing

Hiroto Nakai

Designing section, joined in 2016

Reason why I chose to work for Kawanoe Zoki

Kawanoe Zoki designs and manufactures upon receiving the order. The machine designers pass over the drawings to manufacturing section and the machines, equipment and parts will be completed. I felt this consecutive process is very attractive for me as a machine designer.

Present job

I mainly design the parts drawings. Based on the entire drawings, I make parts drawings.

I strive for fully meeting our customer’s requirements upon their requests.

The project that left the biggest impression on me

In one project, I was in charge of designing the equipment to replace a doctor knife. I designed this equipment considering operator-friendly for easy replacement of the knife.

Before this project, I had been designing by instructions from my seniors, but in this project I carried out my all task by myself which was very impressive.

Motivation

I feel motivated when I can get my tasks done more than my seniors and bosses expected.

Warm and positive environment at my company visit made me feel like

“ I want to be a part of Kawanoe Zoki!!”

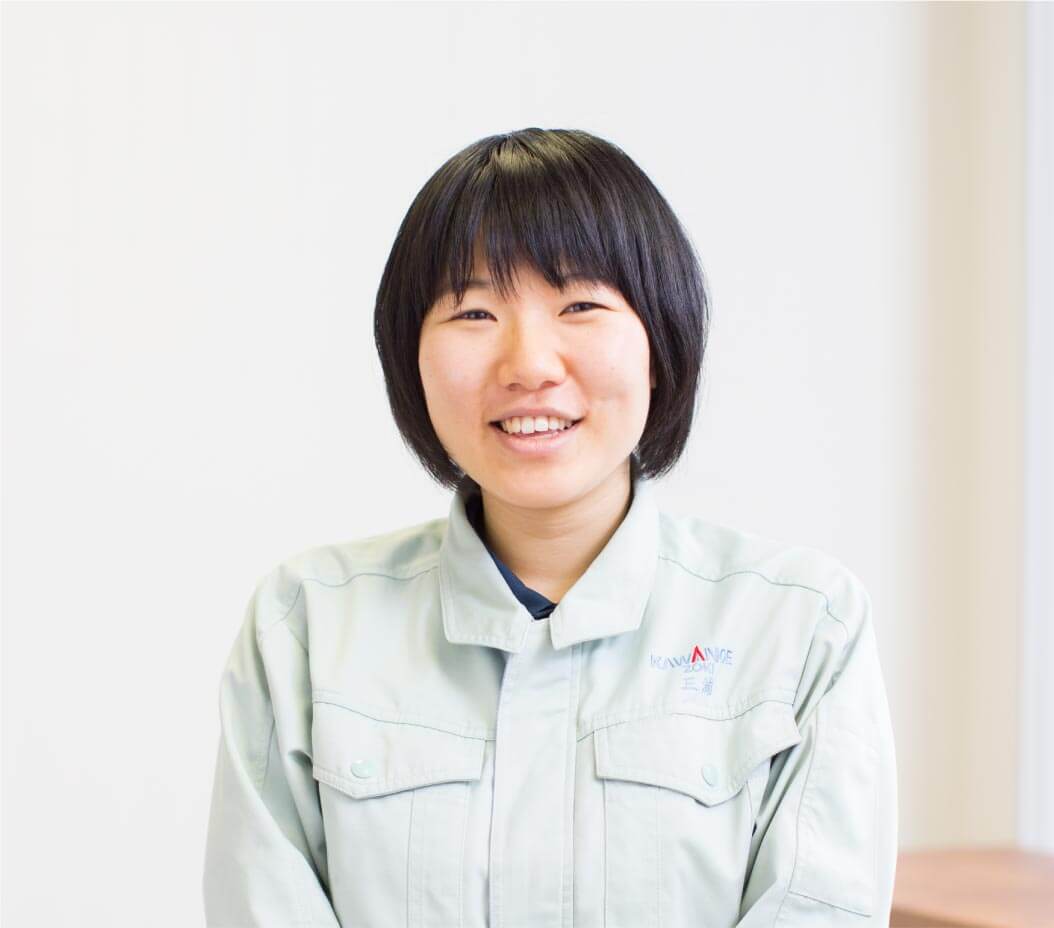

Arisa Miura

Designing section, joined in 2016

Reason why I chose to work for Kawanoe Zoki

At my company visit for job hunting, all Kawanoe staffs warmly welcomed us.

In the mill, they bowed and greeted us even during machining work.

I felt “this company is full of warm hospitality and I want to be a part of Kawanoe Zoki!” After starting to work for this company, I still get a lot of support from my colleagues, seniors and bosses and really enjoy working with them.

Present job

I make 3D prototype drawings. I make the rule of drawings and work on it.

The project that left the biggest impression on me

It is 3D typical model drawing. I was taken this task over from my seniors and worked on it with my other three colleagues. It was very impressive to see our products manufactured based on our 3D drawings.

Motivation

I feel motivated when I see the products manufactured by our drawings.

There used to be some drawings that I had to amend, but gradually I am getting more precise in my drawings.

I mainly work in the office at the moment, but hope to visit our customer’s mill on a business trip in the future.

I wanted to be engaged in a job related to Paper, which is our indigenous industry

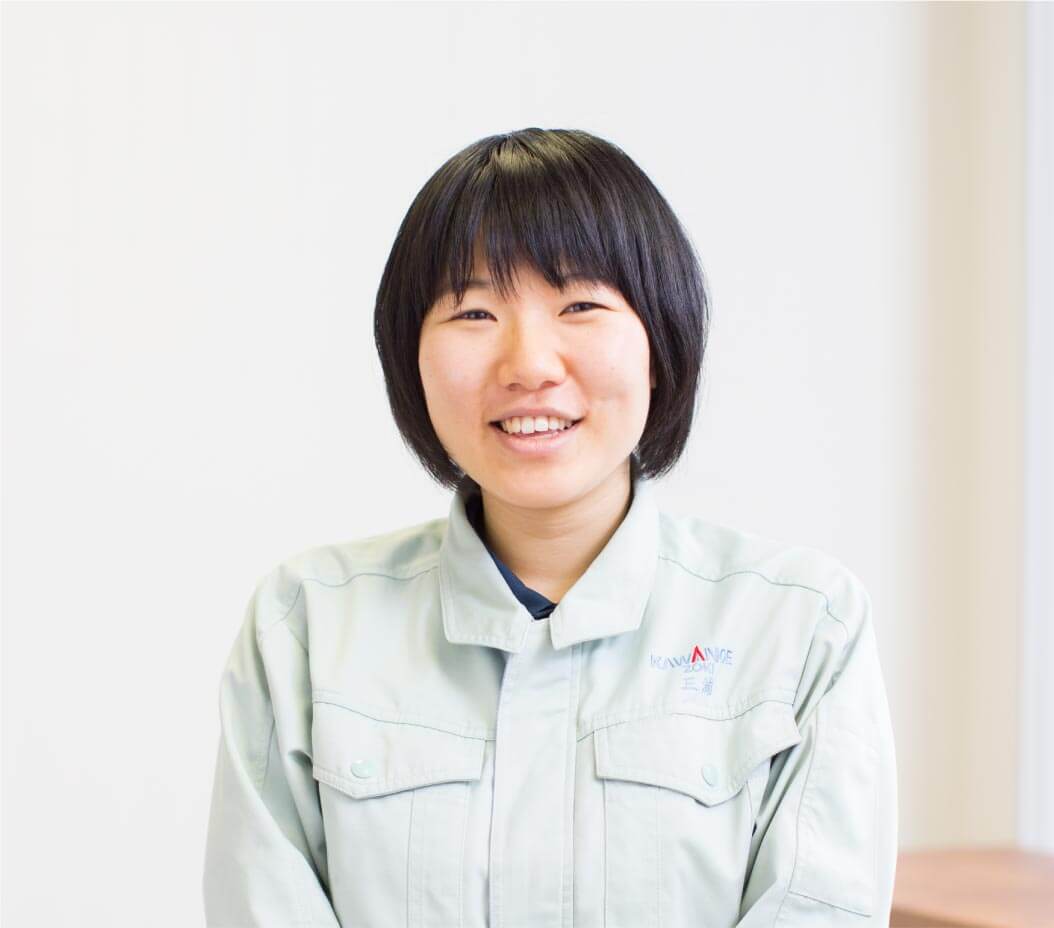

Mihoko Takemura

Designing section, joined in 2017

Reason why I chose to work for Kawanoe Zoki

I started job hunting looking for companies that relate to paper, an indigenous industry in my hometown. If it is machine manufacturer, I thought I can contribute my knowledge and study to the company and here I am in Kawanoe Zoki after the intern. The fact that female staff joined as a machine engineer also made me determine to be a part of Kawanoe Zoki.

On the job training

In my company, newly employed staffs go through each department every three weeks. So far, I designed using CAD, copied the drawing from conventional to 2D drawings, visited suppliers and parts inspection, and machining etc.

In machining section, I prepared for the operation manual of new machining equipment. This manual was appreciated in the office since it helps other staffs operate the machine more efficiently

The project that left the biggest impression on me

It is machining material and milling by laser processing machine. Most of the time during the training, my task was to support seniors, but I was in charge of this laser processing by myself.

It was a good experience because I could consider how it could be more effective without mistakes. In milling, I did drilling.

I studied machinery in university, but haven’t done any training on site. So the experience here in Kawanoe was really good!