Paper Machine

BestFormer Yankee Paper Machine

High quality combined with economical operation.

A dependable tissue machine with a more than 80% share of the Japanese market.

Our “BestFormer” Yankee paper machine is a flagship Kawanoe product that is highly regarded among our customers. The uniform sheet transformation and quality of the paper produced by the patented “BestFormer” is unsurpassed. The operation speed is 1500m/min. and its running costs are significantly low for its class, which means high quality combined with economical operation. Both installation and startup can be completed quickly, and the machine is compact, thereby saving space. It is easy to operate, making it an ideal machine for tissue production. Followed by BestFormer EX Series, which enhanced eco-friendliness and energy saving performance, the latest BF-1500S Advance model has launched in 2017 featuring further developed energy saving performance.

Features

- - High speed production, uniform formation

- - High yield production

- - Low running cost

- - Applicable for wide range of basis weight

- - Short installation period, and quick startup

- - Long life wire, and felt

- - User-friendly

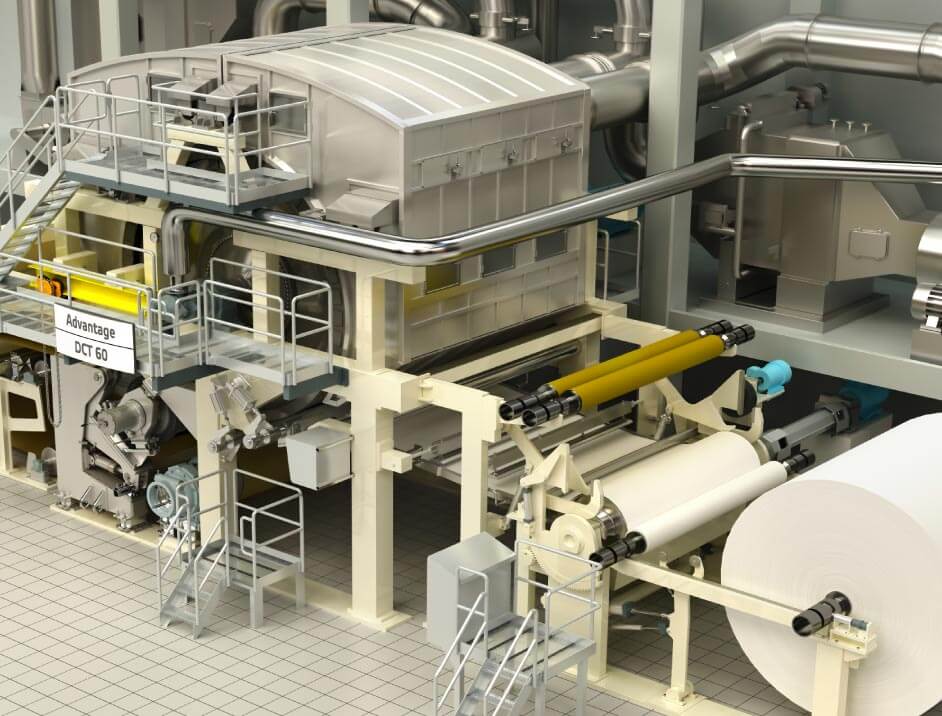

Advantage™DCT®Tissue Machine

Unique features to each part

Provide the best quality of product

Machine speed 2,200m/min is at the top international level.

Soft and intense sheet forming, press configuration with high accuracy and dewatering capacity, dry section with efficient heat transfer and so on, this is the high speed tissue machine with highest performance.

Specification

Advantage DCT 100

- Paper width2850mm(112inch)

- Design speed1600m/min

- Production capacity95ton/day

Advantage DCT 60

- Paper width2850mm(112inch)

- Design speed1300m/min

- Production capacity71ton/day

Advantage DCT 40

- Paper width2850mm(112inch)

- Design speed1000m/min

- Production capacity42ton/day

Dryers

Dryers are indispensable for drying sheet products.

We manufacture large-diameter Yankee dryers for household paper, as well as small-diameter paper dryers for use with paper, specialty paper, etc.

In addition to conventional cast products, we also offer steel dryers that are highly energy-efficient.

In addition to new dryers, we can also replace existing dryers or dryers from other manufacturers.