Industrial Machinery

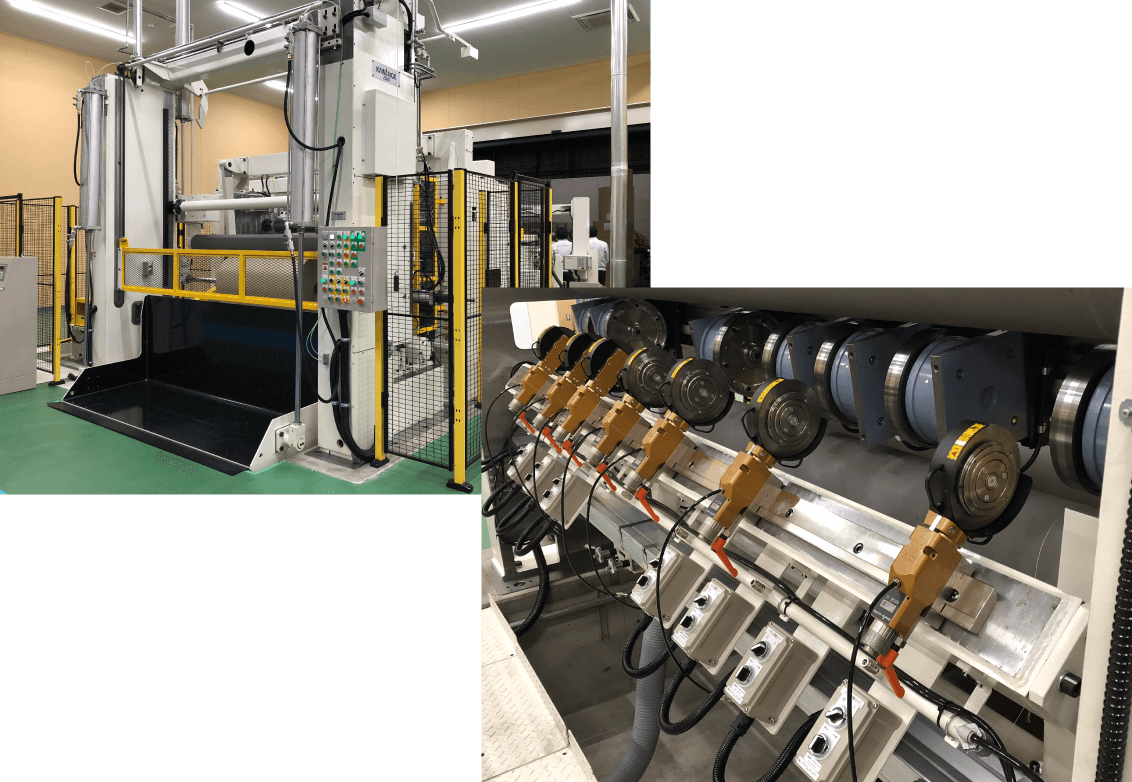

Slitter Winder

We design and propose paper, paperboard, kraft paper, non-woven fabrics, specialty paper, films, etc. to suit a variety of products and applications.

We can design and propose the best solution for your products and applications.

This is a device that winds up the raw material while slitting it into small widths.

NC slitters are numerically controlled for faster and more accurate positioning of multiple slitters.

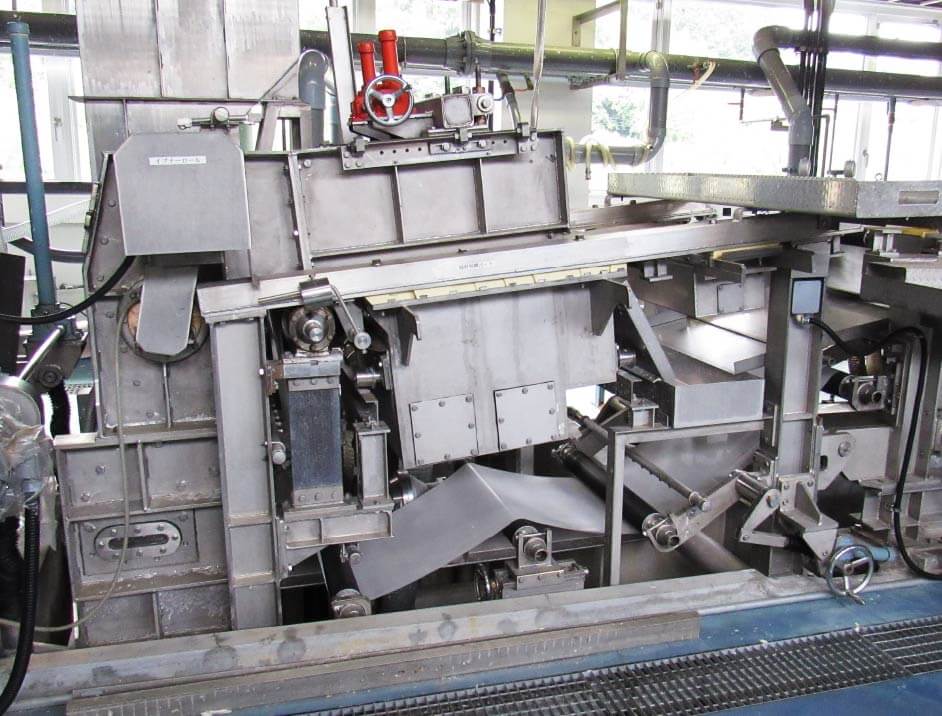

Inclined Wire Paper Machine

Inclined wire paper machines are indispensable for nonwoven fabrics and specialty paper making, where you want to reduce the difference in the sheet's vertical and horizontal strength.

We can design a machine to meet your requirements.

Random Roll Wrapping Machine

The fully automatic random roll wrapping contributes greatly to labor savings and improved operational efficiency.

Kawanoe offers fully automatic roll wrapping to save on labor and improve efficiency. Its high-capacity model with random roll wrapping won the 27th Sasaki Award. This also shows our leading-edge technology.

JW-Ⅱmodel, fully automatic

Full range of equipment from stopper to side wrapping machine

Wrapping capacity 170 rolls / hour automatically

Compilation of Kawanoe Technology

Optional equipment

- - Labeling unit

- - Weighing unit

- - Automatic printing unit

- - Corrugated board pasting machine

- - Side paper punching unit

- - Metal cap attaching unit

High-capacity model with random roll wrapping

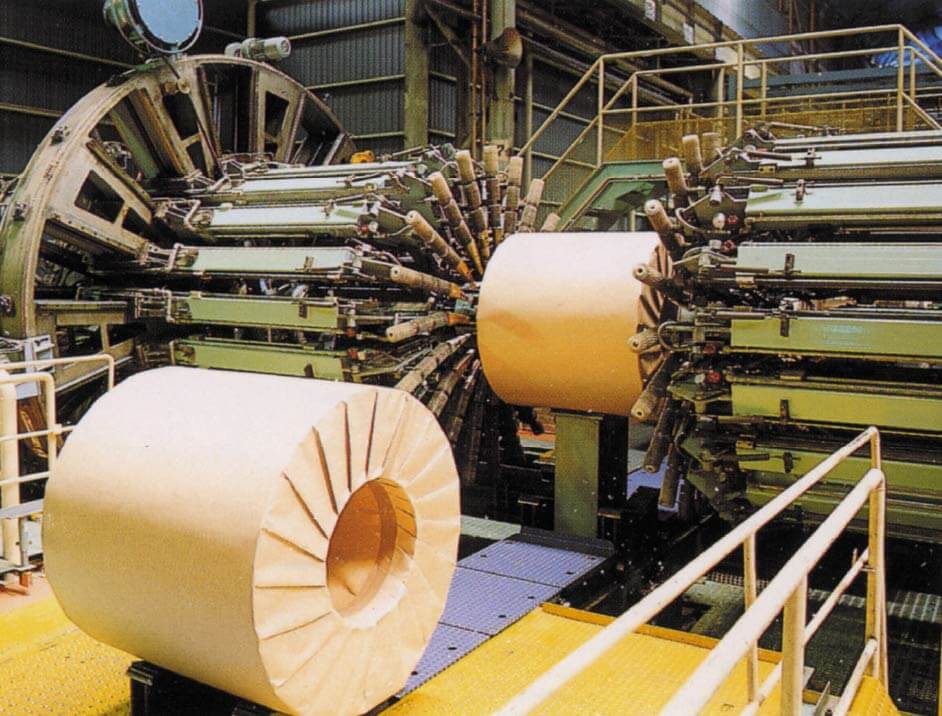

Fully Automatic Steel Coil Wrapping Machine

Labor saving and high efficiency – Fully automated steel coil wrapping

Inner circumference paper inserting machine

Based on dimensions of each coil, turret automatically feeds wrapping paper, which is suitable paper grade and suitable size. Wrapping paper is spread along the inner diameter of each coil.

Roll surface wrapping machine

Based on the coil information, such as dimensions, turret No, turret automatically feeds wrapping paper, which is of suitable paper grade and suitable size, and slit the wrapping paper into the predetermined width. Then, roll surface wrapping supply unit wrap a steel coil with the wrapping paper.

Crimping unit

Automatically crimps the edges of both sides of the wrapping paper, and fold into coil inward, then automatically tape the crimped paper edge.

Specification

| Capacity | Outer diameter | 650 ~ 2,134mm | |

|---|---|---|---|

| Inner diameter | 508,610mm | ||

| Width | 575 ~ 1,880mm | ||

| Weight | MAX 21 ton | ||

| Specification for inner circumference wrapping | Outer diameter | MAX 500mm | |

| Paper width | 1650,2000mm | ||

| Paper grade | OPP, Kraft paper, VCI | ||

| Specification for roll surface wrapping | Outer diameter | MAX 500mm | |

| Paper width | 2,900mm | ||

| OPP, Kraft paper, VCI | |||

| Paper grade | PE, cross-laminate paper, OPP | ||

| cross-laminate paper | |||

| Wrapping capacity | 24.8 coils/hour |