KAWANOE’s Approach

Qualification and skill examination

KAWANOE CHALLENGE SPIRIT

KAWANOE staffs continue to develop the best technology based on our company credo “Work together and flourish together”.

We have the in-house system to support all staffs.

- CAD related work of machinery draughting 1st grade12 people

- Pneumatic device assembly work 1st grade4 people

- Machining Special grade6 people

- Numerically-controlled lathe operation 1st grade6 people

- Manual lathe operation 1st grade6 people

- Numerically-controlled milling machine operation 1st grade16 people

- Planer operation 1st grade1 person

- Slide boring machine operation 1st grade1 person

- Finishing work at machine assembling 1st grade7 people

- Can producing operation 1st grade1 person

- Ordinary class boiler welder3 people

- Steel processing operation for structure 1st grade1 person

- Mechanical inspection work 1st grade2 people

- Certified skilled worker of equipment diagnostics 1st grade5 people

- The third class electric chief engineer1 people

- 2nd class qualified certified electrician1 people

- Condition monitoring and diagnostics of machine personnel 1st grade2 people

- Ultrasonic testing1 person

- Radiographic testing2 person

- Magnetic particle testing4 people

- Penetrant testing3 people

- Certified skilled worker of machine maintenance 1st grade15 people

- Network Specialist1 people

- Information Security Management Examination1 people

- Database Specialist1 people

ISO9001 Quality control

Acquired in 2009

We acquired ISO9001 certification in December 2009.

The purpose of acquiring ISO9001 is to develop a system to offer high quality of service and products.

Target achievement committee

Based on our management policy, each department sets a target every half-year term. We hold target achievement conference to evaluate the achievement for the target.

Also, we regularly hold a training session for ISO internal editor. Those who passed the exam becomes an internal auditor to see if ISO structure is properly exercised in other departments every half-year term.

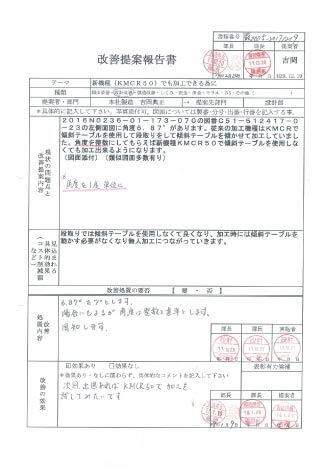

Kaizen activity

This activity is to prevent non-conformance items or matters from recurrence by collecting improvement proposals from our staffs. An effective proposal is commended internally. Internal structure such as this activity is aggregated in “Quality Manual Book” which is distributed to all staffs in order for us to acknowledge the importance.

5S activity

S of 5S activity comes from the initial S of “Seiri (organized), Seiton (in order), Seisou (cleaning), Seiketsu (to be clean), Shitsuke (to discipline)”. This is an activity to improve workplace environment.

5S activity enables all staffs get accustomed to maintain cleanliness at workplace and increase work efficiency.

It also leads to enhance our quality of service as well as staffs motivation.

5S activity is essential to achieve higher production quality.

5S implementation committee

We appoint committee members from each department and hold a meeting to report the progress of the activity and discuss new activity plans.

The members visit each mill to check the status of 5S activity and point out if there find out issues from the different point of view.

It is also beneficial in term of internal activation through 5S activity.

Kawanoe’s approach

Since 2005, we started 5S activity to improve workplace environment by welcoming a seminar instructor giving us lectures.

In the beginning, it created some confusion. However, it is now well established. As a result, our office and mills has been transformed beyond recognition.

Even now, the instructor continues to audit and give us instructions and lectures.

5S improvement report

We make some activity groups within each department and collect 5S improvement reports from each group. Each report is given scores depending on the content of the report.

For the groups with highest scores or high performance, they are commended in the new year conference.

There are a number of improvements to be done. The important thing is to keep in mind that we can always progress to improve.

Community-minded

As a company to be valued by the community and to contribute to the community

To become a company with appreciation and reliability, we strive for further effort on contribution to the community.

Kawanoe Zoki continues to be community-minded for years to come.

Endowment of a stage curtain to Kawanoe elementary school

We have donated a stage curtain to Kawanoe elementary school gymnasium.

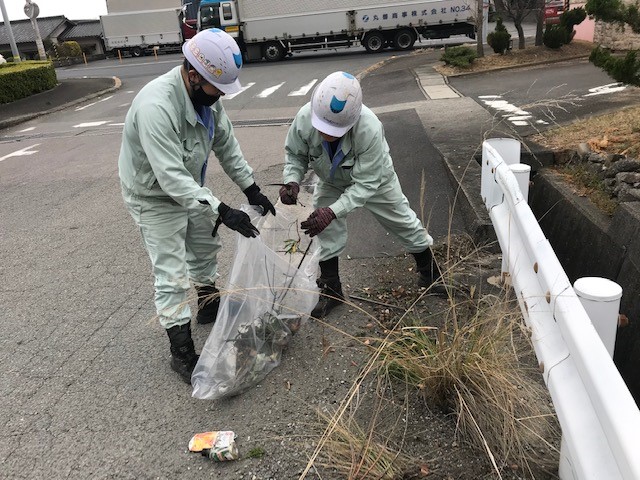

Cleanup activity

As a member of the community, we regularly do a cleanup activity.

We are engaged in cleanup not only around the company but also to the neighboring areas.

Workplace experience by junior high school students at Kawanoe Zoki

We support students through workplace experience in Kawanoe so that the manufacturing industry of our region expands more in the future.