RESEARCH & DEVELOPMENT

Research & Development

Our mission is “Work together and flourish together”.

Aiming to realize the spirit of work “Together with our customers”, we are striving for further effort on research and development working on with our customers.

A variety of test equipment which can comply with different needs is available at Technical Center in order to contribute to future production technology of the customers as well as to offer a place where the research institute such as a university and industry-academia-government can activate the collaboration.

We will continue to promote and improve this facility as a place to provide tips for new research and development.

<Contact us>

E-mail:kawanoe@kawanoe.co.jp

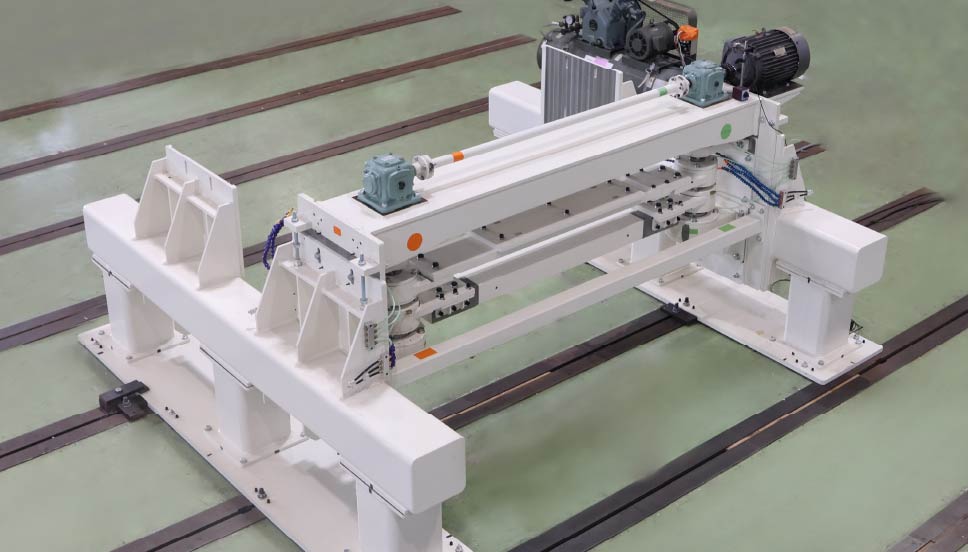

Pilot Converting Machine

We can test some kinds of processed sheets such as paper, non-woven fabric, functional paper and films.

We will work with customers to develop groundbreaking innovations through various processing and data collection at our Pilot Converting Machine.

Specification of Pilot converting machine

- Processing speed 300m/min(Max.)

- Unreel equipment 2 stands

-

Calender equipment

Calender type Steel Calender, Thermal Calender -

Embosser

Embossing type A Variety of emboss patterns

- Large diameter winder φ800mm(Max.)

- Non-stop winder Toilet paper, Kitchen paper size

-

Inter Folder

Adaptable to Folded shapes with various types of folding plates.

Adaptable to width cutting by NC Slitter

Various data collection functions

It is possible to collect detailed data on various operating conditions.

This enables us to confirm the elements necessary for product development and reproduce products through quantification.

The collected data will be compiled and delivered at a later date.

Create Additional Values

By combining various applications of embossers, printers, laminators, and thermal calenders, we can develop new and innovative products.

This is suitable for the development of new products that have never been seen before.

Response to new product development

We can produce various types of roll-up products and folded products suitable for the product form, allowing you to realize the existence of the newly developed product samples.

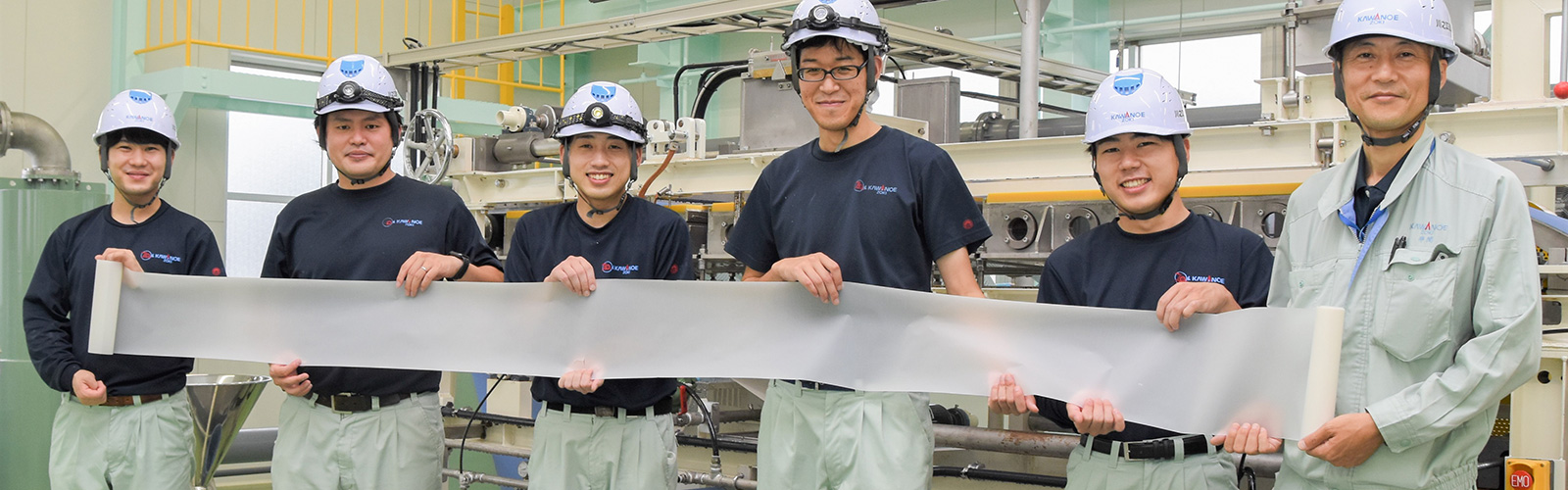

Pilot Machine for cellulose nanofibers(CNF)

Cellulose nanofiber is a new carbon-neutral material derived from plants (wood).

Cellulose nanofiber is the latest material that is made by refined wooden fiber, which is the raw material of paper, to the nano level.

It is one-fifth lighter and five times stronger than steel.

Its use in automotive parts requiring high strength, home appliance housings, and housing construction materials requiring high functionality is expected to contribute to global warming countermeasures because it leads to reduced energy consumption through weight reduction and higher efficiency.

Currently, we are working on developing CNF by continuous molding of materials at our Technical Center through industry-academia collaboration with universities and joint research with various companies.

Pilot oscillating device

Spunlace nonwoven fabrics manufactured by entangling fibers with high-pressure water flow can be tested with the pilot oscillating device.

Oscillating speed can be tested up to 1000 rpm.